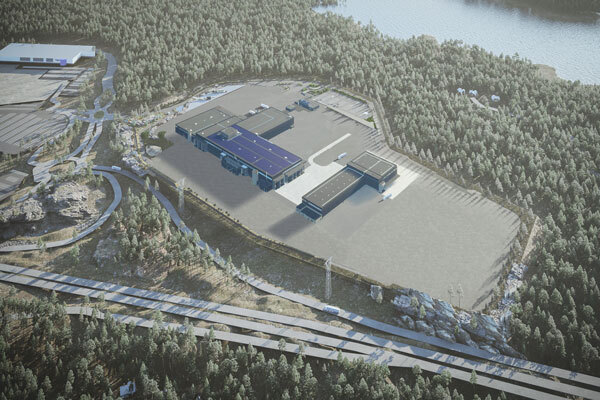

After acquiring the Lokomotion technology center in the Lahdesjärvi neighborhood of Tampere, Finland, in 2021, Metso now plans to move all operations from Hatanpää to this site moving forward. The sustainable technology company will invest $162 million in the first phase of construction for the initial 365,972 sq. ft. of the over-710,400-sq.-ft. new production facility. This phase will bring assembly and testing facilities spaces to manufacture mobile crushers, in addition to storage facilities for components and materials used for aggregates equipment. Metso produces equipment used for the construction of roads and railway tracks, among other infrastructure uses. Construction will begin in 2024 and the facility is expected to become operational by late 2027. The company plans to move its crusher factory, research center, maintenance workshop and offices to the site by the mid-2030s.

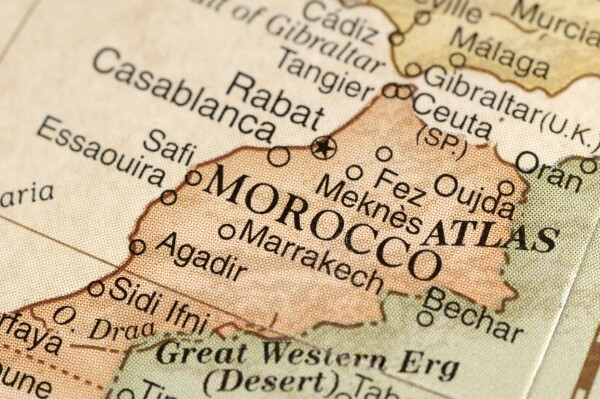

Thanks to a new $1.3 billion investment from Chinese battery manufacturing company Gotion, Morocco has just landed its first EV battery gigafactory. Gotion will initially introduce a battery capacity of 20 gigawatt-hours (GWh) but plans to scale to 100 GWh in years to come. This news follows the company’s plans to look for a European site to expand its EV portfolio, which could include collaboration with another battery manufacturer, InoBat. Gotion has not yet stated whether or not this facility will be shared with InoBat. As the company expands its battery capacity in the future the total investment could come to nearly $6.5 billion, according to the Moroccan prime minister’s office.

The largest direct air capture (DAC) project, appropriately named Mammoth, began its work in Hellisheiði, Iceland, in May 2024. The project comes from Switzerland-based climate technology company Climeworks, looking to replicate DAC operations that found success in the United States. This project reflects Climeworks’ second DAC location in the country after its initial Orca site, which began production in 2021. Mammoth will have the power to capture 10 times more carbon emissions than its predecessor, resulting in 36,000 tons of CO2 captured annually. The regions geothermal energy and natural underground storage capabilities made the location feasible for long-term operations.

Located 38 minutes southwest of Perth in Western Australia, the city of Rockingham has been chosen for mining corporation Rio Tinto’s new $215 million BioIron Research and Development facility. Rockingham Strategic Industrial Area in the city’s eastern region will host the project, which plans to use raw biomass to turn Pilbara iron ore into metallic iron. This method allows the company to reduce its carbon emissions up to 95% and remove the need for coal coking. Once operational in 2026, the facility will welcome 30 new full-time roles. “The world needs low-carbon steel to reach net zero, and we are working to make this a reality by finding better ways to turn our Pilbara ores into steel,” says Rio Tinto Chief Executive, Iron Ore Simon Trott. “BioIron is a world-first technology that has the potential to play a significant role in a low-carbon steel future. This research and development facility will further test the BioIron process, showcase Western Australian innovation capability and further demonstrates Rio Tinto’s commitment to supporting and enabling the decarbonization of the steel industry.”

STMicroelectronics has chosen the Sicilian east coast port city of Catania as the location for a fully integrated 200-millimeter silicon carbide plant. This facility will be the largest of its kind globally and represents a $5 billion investment. Dubbed the Silicon Carbide Campus, the location will be a powerhouse in the company’s global portfolio. According to STMicroelectronics, the site will handle SiC substrate development, epitaxial growth processes, 200-mm front-end wafer fabrication, module back-end assembly, packaging and various R&D ventures. It is anticipated that this location will begin production in 2026, scaling capacity to 15,000 wafers per year in 2033.

Following a meeting between Kazakhstan Prime Minister Olzhas Bektenov and China Nonferrous Metal Mining Co, Ltd. Board of Directors Chairman Xi Zhenping in early June 2024, the company will now move forward with a $1.5 billion copper smelter facility. Located in the country’s Abay region, in the village of Aktogay, the new facility will have the capacity to process 300,000 tons of copper annually and create 1,000 new jobs. When operations begin in 2028 this facility aims to meet domestic market demand for processing raw materials containing copper and copper cathode used in a variety of industries. “The construction of the new copper smelter is a major industrial project that will increase the processing of copper raw materials mined in the country and will make a great contribution to the economy of our country. Copper industry is one of the priority sectors of our industry and its dynamic development is very important for us,” said Bektenov.

Alexis Elmore joined Conway Data in 2022 as associate editor for Site Selection. A 2021 graduate of the University of Georgia, she studied journalism and communications before moving back to Atlanta to pursue her career. As an editor for Site Selection and contributor to Conway's Custom Content guides, she writes about economic development efforts and corporate growth happening around the globe.