ecruiting advanced manufacturing is the strategic weapon of choice for economic development entities competing to create sustainable jobs and investment. However, key questions often arise regarding the definition of advanced manufacturing and the evolving site selection factors most important to this rapidly changing business sector.

What is Advanced Manufacturing?

There is no shortage of definitions for advanced manufacturing. In a broad sense, advanced manufacturing is defined by several key attributes, including intense application of technology to highly integrated processes and implementation of controlled and flexible operations. The result of this process is efficient use of resources, improved supply chain performance, reduced expense and customer pricing, improved quality, and enhanced service performance to customers.

More important than the definition of advanced manufacturing is the value this sector provides in generating high impact economic development outcomes.

Why is Successful Recruiting of Advanced Manufacturing so Important to Economic Developers?

More important than the definition of advanced manufacturing is the value this sector provides in generating high impact economic development outcomes. Successful recruiting of advanced manufacturing facilities is an exceptional job/capital investment creation tool for states and regions desiring to achieve sustainable economic development performance and establish a globally competitive environment for manufacturers.

Other key reasons advanced manufacturing locations are pursued as site location targets include:

Background: The Proliferation of Advanced Manufacturing is an Ongoing Process

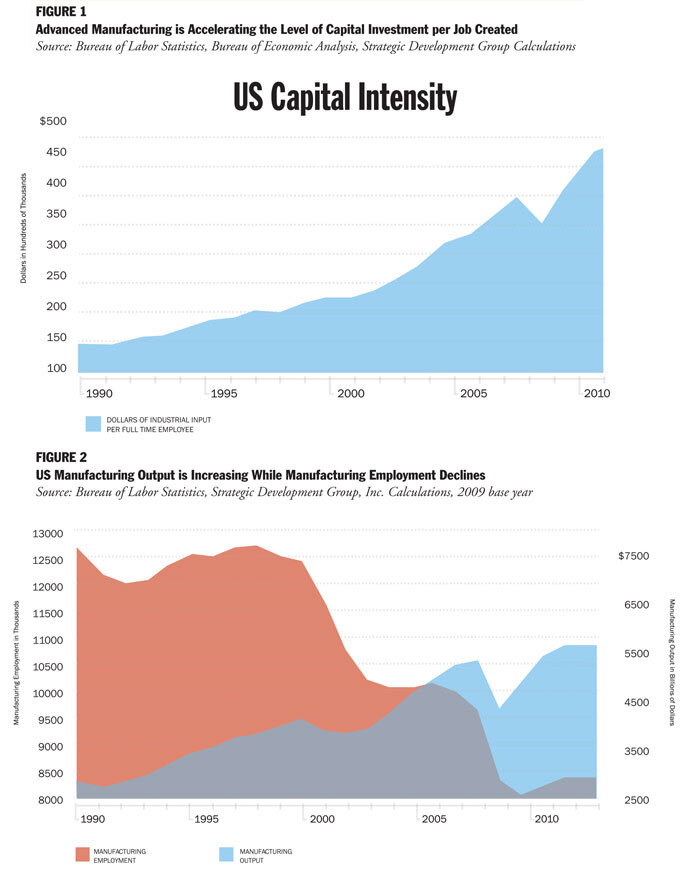

A key attribute of advanced manufacturing is the increase in the ratio of capital invested in plant and equipment relative to the number of new jobs created as a result of this investment. This ratio is defined as capital intensity. Capital intensity in the US has been rising rapidly in recent decades as shown in Figure 1. Advanced manufacturing drives increasing capital intensity as manufacturers incorporate technology and automation. Over recent decades, an increase in productivity and output of manufacturers has resulted in an overall reduction in the size of the US manufacturing workforce, as shown in Figure 2.

Key Site Location Factors for Advanced Manufacturers

In terms of site selection, a key question for economic developers and site selectors is: What are the principal site and community characteristics advanced manufacturers currently require during the site selection process? Traditional site location factors, such as low-cost labor, are less important in successful advanced manufacturing recruiting strategies. Other site location factors are more important for success, including access to a skilled work force that can leverage the highly automated manufacturing processes. The following are some of the key criteria that we have found are increasingly required for advanced manufacturing site selection projects:

Communities must establish and maintain a pipeline of qualified workers that continually learn and evolve as technology develops.

About the Author:

Mark Williams is President of Strategic Development Group, Inc. (SDG), a full service site selection and incentive negotiation firm based in Columbia, S.C. Mr. Williams can be contacted at mwilliams@strategicdev.com. SDG has completed projects resulting in the initiation of over $1.8 billion of manufacturing construction over the last two years..

Mark Williams is President of Strategic Development Group, Inc. (SDG), a full service site selection and incentive negotiation firm based in Columbia, S.C. Mr. Williams can be contacted at mwilliams@strategicdev.com. SDG has completed projects resulting in the initiation of over $1.8 billion of manufacturing construction over the last two years..

Visit www.strategicdev.com to learn more.

Summary:

Successful recruiting of advanced manufacturing facilities and related capital intensity generates significant and sustainable capital investment and jobs.

Through application of innovative technologies and automation, advanced manufacturing site locations bolster an economic development organization’s success and the region’s global competitiveness.

The site selection process for advanced manufacturers is increasingly driven by a number of key site selection factors, one of the most important of which is short and long-term availability of an educated and trained workforce. Communities must establish and maintain a pipeline of qualified workers that continually learn and evolve as technology develops; robust site utility infrastructure, quality of life, financially stable governments and “capital friendly” property tax incentives are also tools for success.

Economic development organizations that meet the site location requirements of advanced manufacturers will compete successfully with US locations and the world for this sector of coveted site location projects.